What materials are Speedi Sleeves made of and how does this impact their performance

What materials are Speedi Sleeves made of and how does this impact their performance

Introduction:

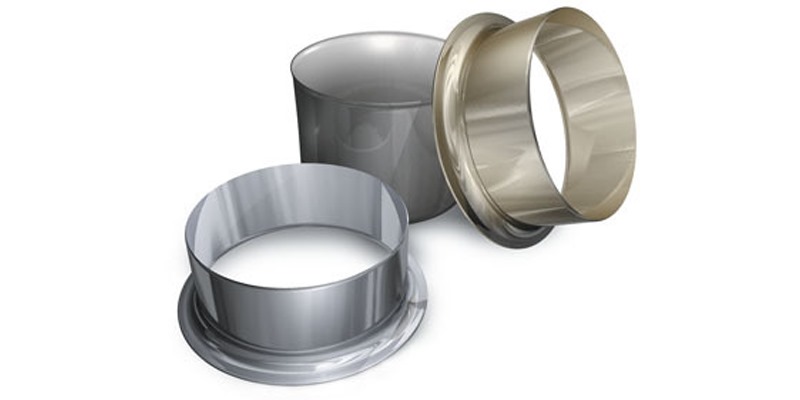

In the intricate world of machinery maintenance, particularly addressing the challenges of grooved and worn shafts for rotary oil seals, the role of Speedi Sleeves emerges as a game-changer. These innovative sleeves provide a quick, economical, and efficient solution for repairing worn shafts, saving both time and resources. In this blog, we will delve into the materials that make Speedi Sleeves exceptional and how their composition impacts their overall performance.

Materials Matter:

Speedi Sleeves are crafted from high-quality stainless steel or other corrosion-resistant materials, ensuring durability and longevity. This choice of materials is pivotal in their ability to withstand the harsh conditions of machinery operation, offering a reliable solution for worn shafts.

Performance Impact:

- Durability:

The use of high-grade stainless steel ensures that Speedi Sleeves are resistant to corrosion and wear. This durability is fundamental in enhancing the overall performance of the sleeve, providing a long-lasting solution for worn shafts.

- Precision Engineering:

The manufacturing process involves precision engineering to meet stringent quality standards. This ensures that Speedi Sleeves maintain consistent dimensions, offering a perfect fit for a wide range of shaft sizes. This precision is crucial in preventing repeated seal replacements and costly re-matching.

- Ease of Installation:

Speedi Sleeves are designed for hassle-free installation. The sleeves can be easily pushed over the worn running surface, eliminating the need for specialized equipment. The inclusion of a standard depth installation tool with the sleeve simplifies the installation process further.

- Cost-Effective Solution:

By providing a cost-effective solution to repair grooved and worn shafts, Speedi Sleeves contribute to significant savings in both time and money. The sleeves extend the life of the shaft, reducing the frequency of seal replacements and minimizing the risk of expensive shaft replacements.

Conclusion:

In the realm of machinery longevity, our Speedi Sleeves stand as a beacon of innovation and efficiency. As the provider of these cutting-edge solutions, we ensure that our sleeves not only meet but exceed expectations. When it comes to elevating the performance and lifespan of your machinery, our Speedi Sleeves become an invaluable asset, embodying our commitment to excellence in every rotation.

Choosing our Speedi Sleeves is an investment in your machinery's longevity and peak performance. Crafted from high-quality materials for durability, our sleeves ensure longevity, withstand operational challenges, and reduce the need for frequent seal replacements. With precision engineering, seamless fitting, and easy installation, they are a cost-effective solution addressing worn shaft challenges, saving you from expensive repairs and replacements over time. Choose us as your trusted partner in machinery maintenance, allowing our Speedi Sleeves to redefine your expectations for efficient, economical, and enduring solutions. Elevate your machinery's performance and embark on a journey of seamless operations with our unrivaled expertise in every rotation.

For more information https://dynamaticfiltrations.com/index.html

For more information https://dynamaticfiltrations.com/index.html